Composite Beams

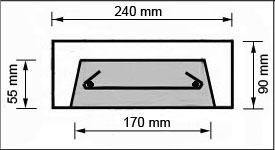

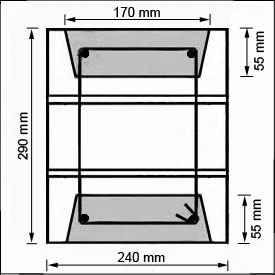

This technique is extensively used in Auroville since 1993. U-shaped CSEB are reinforced with reinforced cement concrete. Reinforcements vary with the span, but the rod diameter cannot exceed ø 12 mm for the Auram blocks 290 & 295 and ø 16 mm for the Auram blocks 240 & 245.

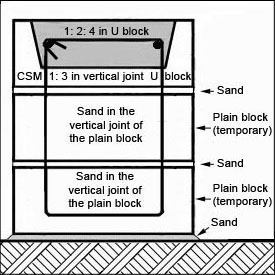

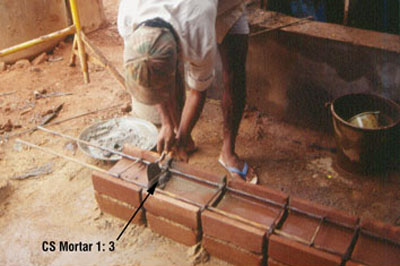

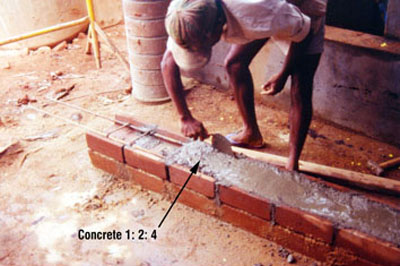

The U blocks are used as lost shuttering, but they also help the compressive strength of the beam. Hence it becomes a composite technique as the reinforced concrete work in tension and the U block works in compression. The concrete cast in the U shape is normally 1 cement: 2 sand: 4 gravel ½’. The vertical mortar in between the U blocks is cement sand mortar CSM 1: 3 of 1 cm thickness. Three types of beams have been developed, elaborated below.

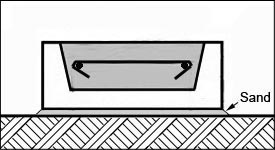

Single height beams (only 1 U block)

– The bottom part of the beam is cast first in a reversed position and after 1 month it is returned:

Either on the ground and the top part is precast in other U blocks or the incomplete beam is lifted with care and the concrete is cast in situ into other U blocks.

– The maximum span for a double height beam will be limited to 2.25 m with 2 steel bars ø 12 mm on the top and 2 steel bars ø 12 mm on the bottom.

– ø 6 mm stirrups are laid in the thickness of the vertical mortar to link the tensile and compressive bars of the beam.

– The horizontal mortar joint is with cement sand mortar CSM 1: 3

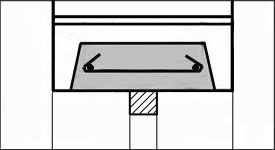

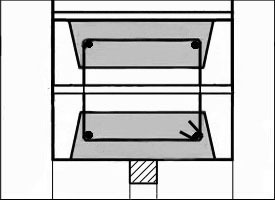

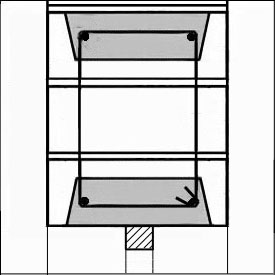

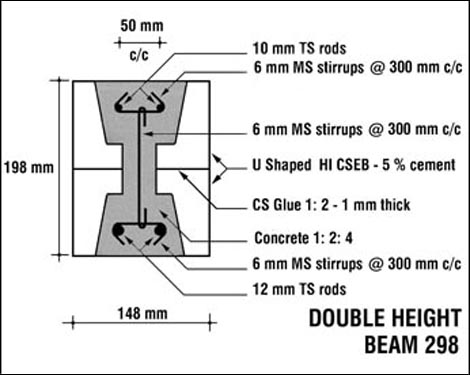

Double height beams (2 U blocks in opposite directions)

– The bottom part of the beam is cast first in a reversed position and after 1 month it is returned:

Either on the ground and the top part is precast in other U blocks or the incomplete beam is lifted with care and the concrete is cast in situ into other U blocks.

– The maximum span for a double height beam will be limited to 2.25 m with 2 steel bars ø 12 mm on the top and 2 steel bars ø 12 mm on the bottom.

– ø 6 mm stirrups are laid in the thickness of the vertical mortar to link the tensile and compressive bars of the beam.

– The horizontal mortar joint is with cement sand mortar CSM 1: 3

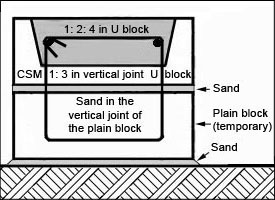

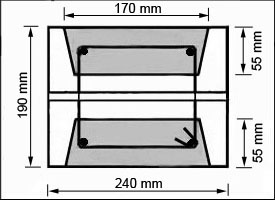

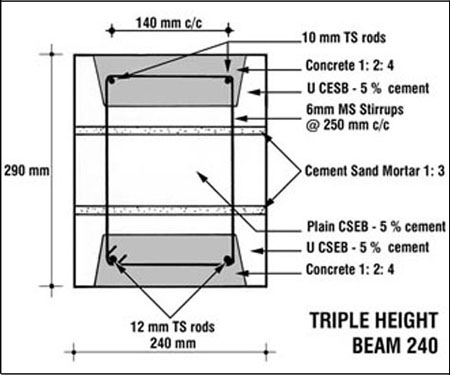

Triple height beams (1 U blocks downwards, 1 plain block in the middle, 1 U block upwards)

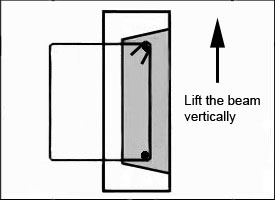

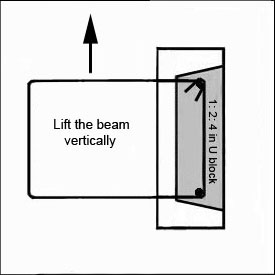

– The bottom part of the beam is cast first in a reversed position.

– After 1 month it is returned and the incomplete beam is lifted with a lot of care and the rest of the beam (plain block in the middle and U block on top) is done in situ in.

– The maximum span for a triple height beam will be limited to 3 m with 2 steel bars ø 12 mm on the top and 2 steel bars ø 12 mm on the bottom.

– ø 6 mm stirrups are laid in the thickness of the vertical mortar to link the tensile and compressive bars of the beam. Note that this triple height beam is rarely precast fully on site as it is too heavy to lift.

– The horizontal mortar joint is with cement sand mortar CSM 1: 3

The main limitation of this technique is the handling of long beams:

– If it is fully precast on the ground, it becomes too heavy to lift by hand. A maximum of 2 m span can be precast and lifted.

– Triple height beams of more than 2 m cannot be precast and they should be lifted incomplete. But the beam is fragile as the section of concrete is only 5.5 cm x 17 cm. Therefore it should be lifted with the section vertically positioned (see drawings above).

Casting a single height beam

Casting a double height beam

Casting a triple height beam

Testing a triple height beam 298 of 2 span

Testing a triple height beam 240 of 2.5 span

Casting a triple height cantilevered beam

Contact US

- Address:Auroville Earth Institute, Auroshilpam, Auroville 605 101 - T.N. India

- Phone:+91 (0) 413 - 262 3330 / 262 3064

- Email:info@earth-auroville.comOpens in your application