Technique Overview

Traditional Rammed Earth

- Earth Dug Out

- Cut Blocks

- Earth Filled In

- Covered Earth

- Traditional Rammed Earth

- Modern Rammed Earth

- Compressed Earth Blocks

- Shaped Earth

- Stacked Earth (Cob)

- Adobe Moulding

- Adobe Buildings

- Extruded Earth

- Wattle and Daub

- Formed Earth (Straw Clay)

- Poured Earth

- Projected Earth

- Termite Wonders

- Views of Earthen Walls

Rammed earth, also known in French as pisé de terre or simply pisé has been used since ages worldwide like many other earth techniques. The earth is mixed thoroughly with water to get a homogeneous humid mix. This humid earth is poured in a form in thin layers and then rammed to increase its density. The increase of density increases as well the compressive strength and the water resistance. Ramming was traditionally done by hand. Since a few decades, ramming is being done mechanically with pneumatic rammers (see the webpage on modern rammed earth).

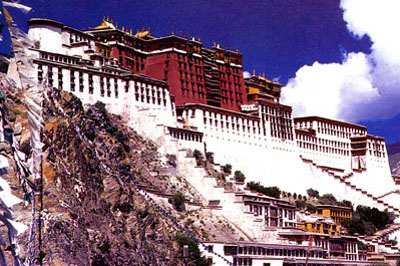

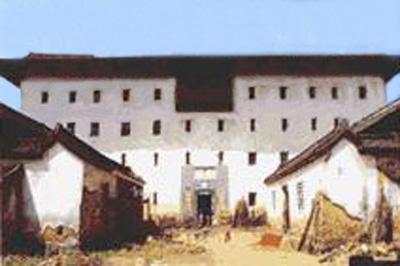

The worldwide tradition of rammed earth construction has shown that it is possible to achieve long lasting and majestic buildings from single to multi storey. Wonderful heritage can be found in countries such as France, Spain, Morocco, China, and all over the Himalayan area. One can see numerous and wonderful examples with all kinds of buildings:

• Farms, or rural houses, chateaux and apartments in Europe

• Entire villages in North Africa

• Parts of the great wall of China

• Buildings in most of the Himalayan regions of Tibet, Bhutan, Nepal, Ladakh

• Widespread examples in South America

Soil identification

Preparation

Formwork types

The horizontal technique was used in many parts of the world. Strips of walls were built horizontally and their height varied from 30 to 90 cm.

The formwork consisted of 2 wooden panels held together with wooden clamps and keys, which were tightened with ropes. Once one portion of a wall was completed, the formwork was immediately dismantled and moved further along the side of the wall, as showed here in Morocco or China.

The vertical technique was used in a few places in the world: mainly in Tibet, China and one region of France (Bugey).

The walls were built vertically to their full height at once. Long poles were anchored in the ground to hold side panels, which were made of wood and tightened with rope. The entire height of the wall was built course after course. Once a course was completed, the side panel was raised to ram a next course and the process went on till the entire height of the wall was completed.

Humid soil was evenly poured into the formwork to get a regular course of about 12-15 cm thickness. Ramming was traditionally done by hand.

The soil is first rammed along the sides of the panels and the central portion of the wall is rammed immediately after that.

Every course is rammed till the rammer hitting the soil gives a clear sharp sound and the rammer is not doing anymore marks on the course.

Once a course has been completed, the process goes on in the same way for the following courses till the maximum height of the panels. Immediately after completion, the formwork is removed and shifted either sideways in the case of the horizontal technique or lifted up for the vertical technique.

Contact US

- Address:Auroville Earth Institute, Auroshilpam, Auroville 605 101 - T.N. India

- Phone:+91 (0) 413 - 262 3330 / 262 3064

- Email:info@earth-auroville.comOpens in your application