Technique Overview

Compressed Earth Blocks

- Earth Dug Out

- Cut Blocks

- Earth Filled In

- Covered Earth

- Traditional Rammed Earth

- Modern Rammed Earth

- Compressed Earth Blocks

- Shaped Earth

- Stacked Earth (Cob)

- Adobe Moulding

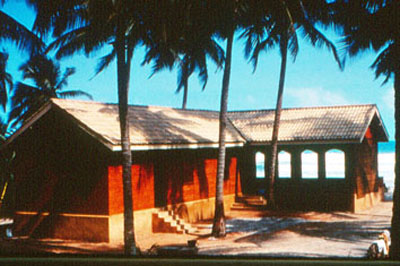

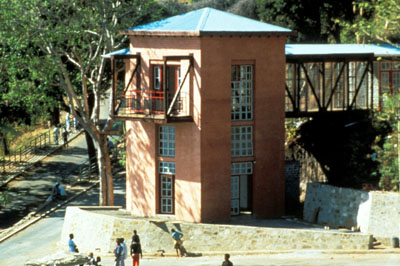

- Adobe Buildings

- Extruded Earth

- Wattle and Daub

- Formed Earth (Straw Clay)

- Poured Earth

- Projected Earth

- Termite Wonders

- Views of Earthen Walls

The soil, raw or stabilized, is slightly moistened, poured into a steel press (with or without stabilizer) and then compressed either with a manual or motorized press. It is a development from traditional rammed earth. It seems that the first attempts at Compressed Earth Blocks (CEB) were tried in France, in the first years of the 19th century: The architect Mr. Francois Cointeraux tried around 1803 to pre-cast small blocks of rammed earth. He used hand rammers to compress humid soil into small wooden moulds which were held with the feet.

One had to wait till 1950 in Colombia for a housing research programme to improve the hand-moulded adobe. The result of this R&D was the Cinvaram, the ancestor of the steel manual presses, which could make very regular blocks in shape and size, denser, stronger and more water resistant than the common adobe. CEB technology has been a great mean for the worldwide renaissance and promotion of earth construction in the 20th century.

The input of soil stabilization allowed building higher with thinner walls, which have a much better compressive strength and water resistance. With cement stabilization, the blocks must be cured for four weeks after manufacturing. After this, they can dry freely and be used like common bricks with a soil cement stabilized mortar. Compressed earth blocks are most of the times stabilised, as showed in the examples hereafter. Hence we prefer to name them now Compressed Stabilised Earth Blocks (CSEB).

Contact US

- Address:Auroville Earth Institute, Auroshilpam, Auroville 605 101 - T.N. India

- Phone:+91 (0) 413 - 262 3330 / 262 3064

- Email:info@earth-auroville.comOpens in your application