La Voûte Nubienne:

Earth Roofs in the Sahel

The information presented hereafter was graciously provided by the members of the Franco-Burkinabé Association, “La Voûte Nubienne” (AVN)

http://www.lavoutenubienne.org/

The context and challenge

The Association La Voûte Nubienne (AVN)

Ashoka Changemakers Innovation Award: The Association la Voûte Nubienne was presented in October 2006 this award for the competition “How to Provide Affordable Housing”. It was granted by the Ashoka foundation and Habitat for Humanity for their programme “Earth roofs in the Sahel.”

La Voûte Nubienne (VN) concept: simplification and codification

The AVN has simplified and codified the vault building technique, which had been developed in Egypt and which is known as the “Nubian vault or technique”. The aim was to enable rural builders and farmers, already familiar with earth brick fabrication and construction, to assimilate it within a relatively short period (i.e. during the traditional winter / spring building season, when agricultural work is minimal). The only raw material used is earth, for making both mortar, and mud bricks dried in the sun (adobes), timber shuttering is not needed to support the vault during construction, and existing traditional methods have been simplified and adapted to provide protection during the short but heavy rainy seasons of sub-Saharan Africa.

A number of specific innovations, taken together, distinguish the VN technique:

• A strict specification of building requirements for foundations, side walls, gable walls, openings, and of course the actual vaults which empirically should not exceed an internal width of ±3.2 m.

• The use of a stranded guide wire stretched between the two gable walls, along which runs a ring with a standard length of cord, to define a constant radius for the initial definition of the vault.

• The transformation of the upper section of the vault from a semi-circular to an elliptical shape, empirically, by the addition of a finger’s length to the radius for each succeeding course of bricks over 70 degrees (thus approaching the ideal, Nubian, catenary curve).

• Use of specially made bricks for the vault, composed of high quality earth (i.e. as used for granaries) mixed with straw, with optimal dimensions of ~ 24 cm long x 12 cm wide x 4.5 cm thick, light enough to stick to the fresh mortar near the top of the vault.

• The inclination of the brick rows of the vault to a lower angle than vertical (±60°), to make the already built rows bear a part of the load of the rows actually being built.

• Use of oil drums as temporary supports for forming window and door arches.

• The use of plastic sheeting over the roof, covered by a final waterproof rendering (at least 6 cm deep) to protect it from solar degradation, and to reduce the annual maintenance load for the roof

Foundations and walls

Depending on the properties of the ground and the site of the building, foundations can vary from 20 to 45 cm deep. They are filled with rocks, bound with an ordinary earth mortar. In sites where there may be strong flows of surface water during the rainy season, the foundations may be raised 10 – 15 cm above ground level.

Load-bearing walls which carry the vault are around 60 cm thick (depending on the dimensions of the brick moulds being used). The courses are built with an alternate bond pattern of stretcher and headers. Recesses and openings are built into the thickness of the walls, for doors, windows, cupboards, alcoves, and shelving. These are headed with arched lintels (built over oil drums as a temporary support); their use can be modified according to the needs of the owner. These are built before construction of the main vaults starts.

Gable walls are built with courses of bricks laid in header, and are around 40 cm thick. They are raised to lean slightly inwards (by around 1.5 cm for each metre of height).

Vault construction

Vaults are built without any shuttering. The adobe bricks which are used to build the vault are very flat ones: 24 cm x 12 cm x 4.5 cm. They are often made of the same soil used for building granaries. The bricklayer, using a mortar made from the same earth, starts the vault by laying the first courses against one of the gable walls

A cable made of six steel wires coiled together is stretched between the two gable walls, at the height of the base of the vault. This defines the central axis of the vault, and a cord fixed to a sliding ring on the cable acts as a guide to ensure that the bricklayer maintains a constant radius for the vault. The upper section of the vault is transformed empirically from a semi-circular to an elliptical shape, by the addition of a finger’s length to the radius for each succeeding course of bricks over 70°.

The builder alternates work on the top of the vault, which requires some waiting time between each course for the mortar to dry, and the sides, which are easier to construct. Buttresses are formed on the completed vaults by raising the side walls by 8 to 10 courses of large bricks, and by filling the gap so created with plain earth.

Finally, the roof is waterproofed, using plastic sheeting (locally manufactured FasoPlast, costing around 400 CFA francs/m2), over a smooth coat of mud mortar. The sheeting is then covered with a rendering around 5 cm deep of enriched mud mortar (using traditional additives), which both protects the plastic from damage by the sun, and provides additional protection against heavy rains.

Training of apprentices takes place exclusively on the job, on VN building sites, under the guidance of a VN builder; familiar tools are used for the work, with no need for special devices or machinery. This method matches perfectly with deeply embedded cultural traditions, and encourages local and community involvement in construction. The time needed to learn how to build a VN house depends on the previous skills of the apprentice (a farmer with no prior building expertise will need more time than an experienced builder who just needs to learn the vault construction technique).

Builders and apprentices who want to be trained in using the VN technique are asked to contact the project office at Boromo. After coming to an agreement, board, lodging, and transport to the relevant building sites, is provided (as well as a monthly payment of about 25,000 CFA francs, depending on experience, and progress made). At the end of the apprenticeship period, trained builders can either set themselves up as individual entrepreneurs (with help from the Association’s network of contacts), and/or in agreement with the Association, become trainers themselves.

It is not an easy task to compare costs between a VN house and the houses built with “modern techniques” or the traditional ones with timber support for the roof terrace. Thermal insulation / comfort qualities are very different: a VN house is far more comfortable and better insulated from heat and cold than one with a tin roof. And in many parts of the Sahel, the traditional timber support and earth flat roof terrace is no longer an option.

Furthermore, the costs of a VN house vary from region to region (higher in urban than in rural zones, because of the transportation cost of adobes). The cost depends also on climatic conditions (availability of water for making bricks and mortar). Costs of materials are very different, with imported tin roofing materials and beams, and cement and concrete blocks, costing far more in cash than earth bricks made in a village environment; but this is partly balanced by the fact that a VN house will require around three times as many earth bricks as a tin roof house

Furthermore, the cost proportion of labour to materials differs significantly from one method to another. The labour component in a VN house is much higher than for a tin roof house, thus providing employment and livelihood opportunities to people. There are also differences in ongoing maintenance costs, with earth roof VN houses requiring some maintenance and re-rendering every two years or so, after the end of the rainy season (however, the skills needed for such maintenance are well known, having been practised for generations on the traditional flat roof houses, and on communal buildings such as mosques).

A detailed evaluation of comparative costs of VN methods with the alternatives, in Burkina Faso concluded that a VN house in a rural zone can be up to 30% less expensive, on average, than an earth wall + corrugated iron roof house of the same size; however, in an urban milieu this advantage is lost, because of the cost of transporting the bricks from outside. Overall, the advantage of the VN method lays not so much in the fact that it may be ‘cheaper’, but that:

• The raw materials can be extracted, made, and transported locally;

• The client can, if required, provide a significant proportion of the labour;

• Payment for labour can be on a barter basis, outside formal economic circuits.

And, for sure, a VN house is far more comfortable and more agreeable to live in than one with a corrugated iron roof!

The AVN has prepared for builders and clients five standard house plans, based on different permutations and combinations of one or more basic vaulted units; these range from a two-bedroom house to a simple ‘bachelor pad’.

Many examples have already arisen of adaptations and modifications of the VN technique, both by clients and builders, ranging from the very simple to the most sophisticated. Initial plans and dimensions have been changed, and improvements made to the layout and finishes, depending on clients’ aspirations and resources. Such innovations enrich the scope of the VN principle, provided the basic technical principles of vault construction are respected.

Examples of popular modifications of interiors include integrating an electrical supply into the masonry, cement rendering of the lower half of internal walls, and interior showers with cement floors and tiling.

Modifications which reduce the maintenance load inherent to all earth-built constructions include: use of a mixture of sand, mud, oil, and tar for external rendering and roofs, cement rendering of external surfaces, with a tar finish to the roof, and use of locally produced laterite bricks, or clay fired bricks, for the gable walls and the external courses of load-bearing walls.

It is possible to combine the VN earth-built technique with more modern materials and techniques, such as concrete beams and pillars, to create larger internal volumes for communal buildings such as churches and community centres.

Training through apprenticeship

Training of apprentices takes place exclusively on the job, on VN building sites, under the guidance of a VN builder; familiar tools are used for the work, with no need for special devices or machinery. This method matches perfectly with deeply embedded cultural traditions, and encourages local and community involvement in construction. The time needed to learn how to build a VN house depends on the previous skills of the apprentice (a farmer with no prior building expertise will need more time than an experienced builder who just needs to learn the vault construction technique).

Builders and apprentices who want to be trained in using the VN technique are asked to contact the project office at Boromo. After coming to an agreement, board, lodging, and transport to the relevant building sites, is provided (as well as a monthly payment of about 25,000 CFA francs, depending on experience, and progress made). At the end of the apprenticeship period, trained builders can either set themselves up as individual entrepreneurs (with help from the Association’s network of contacts), and/or in agreement with the Association, become trainers themselves.

Comparative costs

It is not an easy task to compare costs between a VN house and the houses built with “modern techniques” or the traditional ones with timber support for the roof terrace. Thermal insulation / comfort qualities are very different: a VN house is far more comfortable and better insulated from heat and cold than one with a tin roof. And in many parts of the Sahel, the traditional timber support and earth flat roof terrace is no longer an option.

Furthermore, the costs of a VN house vary from region to region (higher in urban than in rural zones, because of the transportation cost of adobes). The cost depends also on climatic conditions (availability of water for making bricks and mortar). Costs of materials are very different, with imported tin roofing materials and beams, and cement and concrete blocks, costing far more in cash than earth bricks made in a village environment; but this is partly balanced by the fact that a VN house will require around three times as many earth bricks as a tin roof house

Furthermore, the cost proportion of labour to materials differs significantly from one method to another. The labour component in a VN house is much higher than for a tin roof house, thus providing employment and livelihood opportunities to people. There are also differences in ongoing maintenance costs, with earth roof VN houses requiring some maintenance and re-rendering every two years or so, after the end of the rainy season (however, the skills needed for such maintenance are well known, having been practised for generations on the traditional flat roof houses, and on communal buildings such as mosques).

A detailed evaluation of comparative costs of VN methods with the alternatives, in Burkina Faso concluded that a VN house in a rural zone can be up to 30% less expensive, on average, than an earth wall + corrugated iron roof house of the same size; however, in an urban milieu this advantage is lost, because of the cost of transporting the bricks from outside. Overall, the advantage of the VN method lays not so much in the fact that it may be ‘cheaper’, but that:

• The raw materials can be extracted, made, and transported locally;

• The client can, if required, provide a significant proportion of the labour;

• Payment for labour can be on a barter basis, outside formal economic circuits.

And, for sure, a VN house is far more comfortable and more agreeable to live in than one with a corrugated iron roof!

Modularity and customization

The AVN has prepared for builders and clients five standard house plans, based on different permutations and combinations of one or more basic vaulted units; these range from a two-bedroom house to a simple ‘bachelor pad’.

Many examples have already arisen of adaptations and modifications of the VN technique, both by clients and builders, ranging from the very simple to the most sophisticated. Initial plans and dimensions have been changed, and improvements made to the layout and finishes, depending on clients’ aspirations and resources. Such innovations enrich the scope of the VN principle, provided the basic technical principles of vault construction are respected.

Examples of popular modifications of interiors include integrating an electrical supply into the masonry, cement rendering of the lower half of internal walls, and interior showers with cement floors and tiling.

Modifications which reduce the maintenance load inherent to all earth-built constructions include: use of a mixture of sand, mud, oil, and tar for external rendering and roofs, cement rendering of external surfaces, with a tar finish to the roof, and use of locally produced laterite bricks, or clay fired bricks, for the gable walls and the external courses of load-bearing walls.

It is possible to combine the VN earth-built technique with more modern materials and techniques, such as concrete beams and pillars, to create larger internal volumes for communal buildings such as churches and community centres.

CASE STUDY 1

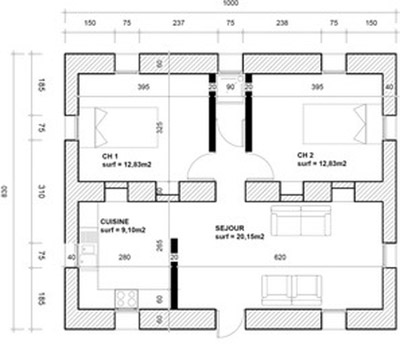

Standard two-vault house

The standard two-vault house (living room, 2 bedrooms, shower and kitchen) has around 50 m2 interior floor space. The usable area can be increased by transforming the roof into a flat terrace. The labour required for such a house is around 26 man days of two builders, and the same again for two apprentices and two labourers; materials needed are 30 barrows of laterite rocks, 4300 large bricks and 130 barrows of ordinary earth for the walls, 70 barrows of good quality earth for the vault bricks and mortar, and 150 barrels of water. Total cost (excluding land) for labour, materials, and finishes is the equivalent of around 800 USD.

CASE STUDY 2

A two-storey house

Several two-storey VN houses have now been built. The house showed in the photos below (not in the plan, which is for a larger, five-vault house) at Boromo has three vaults on the ground floor, with a flat roof which supports a further vault, with a roof terrace on either side. Total usable interior floor space is 110 m2. Total cost, excluding the site, is the equivalent of about 2,000 USD (labour 650 USD/ materials: 600 USD / finishes: 750 USD).

CASE STUDY 3

A mosque

The first VN mosque in Burkina Faso was built during the winter of 2005/2006. The construction was financed by a family from Ouagadougou, and was built in their home village of Kagalé (Kongoussi zone), with active participation from many of the villagers. The plans were drawn up by Urs Wyss, a structural engineer based in Ouagadougou, who also acts as a technical advisor to the VN Association. The ground floor of the mosque is composed of two large vaults side-by-side, with many arched openings between them to provide a relatively large floor area of 70 m2. An external staircase on the flank leads to two small vaults on the roof, one for the call to prayers, the other a minaret. Total cost was the equivalent of about 1,050 USD, including labour, materials, and finishes (excluding the land).

Contact US

- Address:Auroville Earth Institute, Auroshilpam, Auroville 605 101 - T.N. India

- Phone:+91 (0) 413 - 262 3330 / 262 3064

- Email:info@earth-auroville.comOpens in your application