Mayotte as a development model with cseb

The information presented hereafter was graciously given by the team of CRATerre ENSAG

craterre@club-internet.fr – http://www.craterre.archi.fr

Mayotte is a French Territory in the Indian Ocean, with a population of 50,000 people.

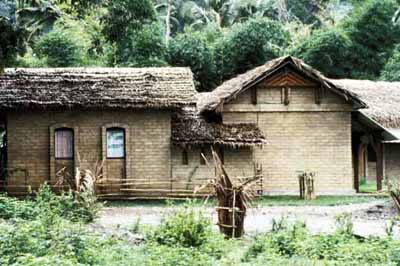

A programme for the global improvement of the housing stock of the Island of Mayotte was launched in 1978 and 1979. The objective of the programme was to achieve, over a period of 20 years, decent conditions within the islands very precarious traditional housing, which reflected an economic situation comparable to that of neighbouring developing countries (such as Madagascar, Tanzania and Mozambique).

Since most of the rural population had no financial resources, it was been necessary to turn to self-help building capacities, local crafts and local resources in materials and skills. Therefore CSEB was chosen as one of the privileged building material.

The first goal was that 7,500 housing units were supposed to be restored or rebuilt by 1990. In 1991 6,000 social housing units and more than 500 rented accommodation units had been completed, mainly built with compressed stabilised earth blocks.

The last survey done in 2000, after about 20 years of development, showed that around 30,465,000 blocks had been produced for building about ~ 955,000 m2 of walls which represents about 12,500 houses. As the development process set up in Mayotte is going on, much more houses have been built up to today.

Framework Of The Project

Political will and the initial strategy

From the outset, it was clearly understood that the activity generated by the building sector would serve to providing the Island of Mayotte with an economic structure. Being an island, the maximum use of local resources was set up as a governing principle.

The first step towards this aim was a survey of Mayotte housing, undertaken from an ethnological point of view. The survey established that the structure of the islands village-organized housing was extremely homogeneous. But at the same time, the technical diagnosis stated that the islands built housing stock (~ 10,000 dwellings/plots) was very poor:

• 85 % of dwellings had no water, either inside or within the plot

• 95 % had no electricity

• 83 % were roofed with coconut palm leaves and 17 % with corrugated iron

• 90 % had walls built with organic materials (raffia, coconut palm leaves, etc.) or wattle and daub

A general policy for the improvement of living conditions and the structuring of the production means was defined with the underlying intention to promote the islands human and material resources and also to allow the development of outlying areas of Mamoudzou, the largest town.

Structures set up

In order to implement these social housing schemes, the following operational framework was set up:

• A social housing team within the “Direction de lEquipement” (Department of Public Works) to design the programmes and coordinate their implementation.

• An association made up of members of the public, elected representatives, and administrators to assist in the design and evaluation of the programmes.

• A State Mixed Economy Company was created – La Société Immobilière de Mayotte (SIM) – to take charge of the building of administrators housing and to manage the social housing programme.

• A cooperative named “Musada” (mutual aid), enabling supplies of materials, tools, and site equipment for skilled workers to be grouped, testing new materials, training and equipping skilled workers, and acting as a labour pool.

• An association for professional, continuous training (APFPC) to give practical training in building skills, masonry, roofing and carpentry, to young islanders with no qualifications or to already established craftsmen but with few qualifications, through the “Compagnons du Devoir” (a French trades’ guild).

Finance

A personal contribution was compulsory, either with funds or materials and labour. It was a fundamental principle for not indebting households. The basic conditions were as follows:

• Serviced plots, with nominal viability of extension areas for island villages and a method of allocation which follows the principles of customary right.

• Help with construction work, in two main forms:

– Help in kind: by supply of materials and technical assistance for the construction of a two-room dwelling of 40 m2 that the beneficiary is expected to finish.

– Mayotte social housing: a model housing of 50 m2 was jointly financed by a grant and an individual contribution with materials and labour. An agreement was made for the repayment of part of the grant in the form of rent-repayments over 6 to 10 years.

Early achievements

The conceptual coherence of the programme, defined in 1978, and the care with which it was implemented led to spectacular results in just about thirteen years of development, as showed in the following table.

| NATURE OF CONSTRUCTION AND MATERIALS | RURAL AREAS | URBAN AREAS | OVERALL |

| Shelter built with earth | 2,320 | 2,680 | 5,000 |

| “Help in kind” (compressed stabilised earth blocks) | 3,450 | 2,250 | 5,700 |

| Model housing (compressed stabilised earth blocks) | 100 | 104 | 204 |

| SUB TOTAL (HOUSES WITH EARTH) | 5,870 | 5,034 | 10,904 |

| Shelter built with organic materials | 1,000 | 500 | 1,500 |

| “Kripi” shelter (earth plastered onto stone-filled framework) | 1,050 | 1,500 | 2,550 |

| Corrugated iron roofing | 96 | 104 | 200 |

| Cement block housing | 430 | 1,200 | 1630 |

| Stone housing (basalt) | 150 | 140 | 290 |

| Rented accommodation (earth, stone, cement blocks) | 123 | 363 | 486 |

| Private top quality housing | 15 | 25 | 40 |

| SUB TOTAL (OTHER TYPES OF HOUSES) | 2,864 | 3,832 | 6,696 |

| GRAND TOTAL | 8,734 | 8,866 | 17,600 |

Organized production chains of other local materials

Building with Earth

Earth as a lever for development and management of resources

Exploiting a local resource meant undertaking a wide programme to identify which of the islands raw materials were suitable and available in sufficient quantities to be exploited for construction purposes.

Over 10 years, between 1978 and 1988, a number of quarries were opened to excavate rock type materials (required for the production of aggregates, i.e. gravel and crushed stone), lateritic soils and loose volcanic ash (pozzolana), basalt stone, etc.

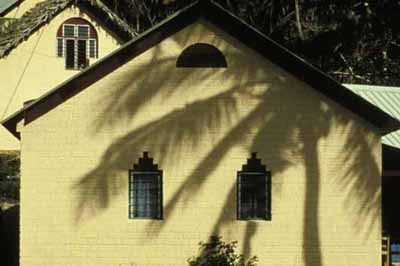

The organized production of stabilised raw earth was launched with the techno economic assistance of CRATerre ENSAG between 1980 and 1982. About 20 quarries and a network of 19 blockyards were set up throughout the island. This was initially managed by the SIM and the Musada. This launching of production of compressed stabilized earth blocks (CSEB) helped to set up a genuine small local “industry”, creating and redistributing wealth:

• Creating wealth by exploiting the islands mineral resources and by building up a considerable stock of materials (from 176,000 blocks in 1982 to 3,500,000 in 1989 and about 30,500,000 in 2000) with the aim of building up an architectural heritage.

• Redistributing wealth by creating numerous jobs throughout the production chain, from quarry workers to block makers, distribution activities, masons, roof workers, carpenters, etc. All were trained in the course of time.

Acceptance of CSEB

The main factors contributing to this acceptance have been:

• The use of Belgium made soil block presses, Terstaram, which gave to the earth a fresh and technical image;

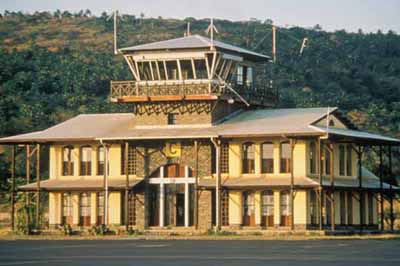

• The multiplicity of building works for the building of public facilities;

• The fact that housing for expatriate French civil servants has been built with earth blocks, along the same construction lines as those of the social housing units;

• The training for block makers and masons;

• The commitment of local architects, whose projects made maximum use of compressed stabilised earth blocks, and minimized the use of sand cement blocks and concrete;

• The production of a wide range of housing, designed to be easy to implement, whilst broadening the spectrum of products.

Cost comparisons

| Cost comparison of sand-cement blocks and CSEB (1982) | ||

| Cost of wall per m2 | Sand- cement block (FF) | CSEB (FF) |

| Soil | – | 8.70 = 10.87 % |

| Sand | 21.85 = 20.23 % | – |

| Cement | 42.70 = 39.54 % | 23.90 = 29.87 % |

| Water | 0.72 = 0.66 % | 0.91 = 1.14 % |

| Power | 0.72 = 0.66 % | – |

| Investment | 5.90 = 5.46 % | 3.10 = 3.87 % |

| Production labour | 8.25 = 7.63 % | 15.70 = 19.62 % |

| Construction labour | 28.00 = 25.72 % | 28.00 = 34.63 % |

| TOTAL | 108.14 = 100 % | 80.31 = 100 % |

| Cost comparison per m2 of various walls (1991) (un rendered, with internal and external varnish) | |||

| CSEB wall | Fired brick | Sand cement blocks | Stone |

| 303.62 FF | 560.42 FF | 474.50 FF | 581.00 FF |

The organizations commissioning building works have today links with a series of construction actors: Building contractors, small and medium sized enterprises, numerous skilled workers, a structure for teaching and professional training, and a structure for job promotion.

Today, this production mechanism in Mayotte is an enormous enabling machine, which has succeeded in giving the islanders an essential role to play by integrating them relatively quickly into all sectors of the economy. There is no doubt that it is the primary sector, dominated by building, which nourishes and stimulates the local economy. This sector has managed to create 2,300 salaried jobs, accounting for 30% of total salaried jobs in the total employment structure.

Outcome in 2000

| CONSTRUCTIONS BY THE SIM | PUBLIC | |||

| Social housing | Rental housing | Promotion by SIM | CONSTRUCTIONS | TOTAL | |

| Number of blocks | 21,040,000 | 8,525,000 | 350,000 | 550,000 | 30,465,000 |

| Percentage | 69.1 % | 28.0 % | 1.2 % | 1.8 % | 100. 0% |

| Area of walls | – | – | – | – | ~ 955,000 m2 |

| Number of houses | – | – | – | – | ~ 12,500 units |

Note that the data showed above are taken from a survey done in 2000.

But as the development process set up in Mayotte is going on, these numbers are today far below the reality.

Mayotte as an Integrated Development Model

Outcome in 2000

The Mayotte experience has showed that the objective of the creation and gradual consolidation of a local production structure must be actively supported by the political will to invest first and foremost in the following essential areas:

- Ethnological housing surveys to ensure the identification of local building cultures, habits and customs related to shelter, the needs and aspirations of populations, their economic resources, and the means at their disposal for mobilizing housing production.

- Surveys to identify raw material resources which might give rise to the organized production of local building materials.

- Techno-economic feasibility studies for the setting-up of such organized production based on the exploitation of resources considered as promising.

- Undertaking research and development, enabling the testing, evaluation and improvement of local materials and products useful for construction, as well as constructional and architectural models.

- Setting up structures for the implementation of social housing, providing a framework for action and the financial, administrative, juridical and technical tools both enabling the overall coordination of production and allowing the personalized management of operations.

- Setting up structures of a cooperative nature, enabling stocks of materials and building elements to be acquired, retail costs to be regulated, and playing a part in the promotion of local technologies and labour in the building sector.

- The indispensable development of training with a view to overcoming the lack of qualified local staff, and the setting up of an employment policy intended to ensure local professional recognition of the qualifications created.

- Setting up of a framework for the structured financing of housing production to achieve a fair balance to subsidies, loans or rents, to means of local participation in kind (labour and materials).

- The setting up of a framework for structured financing suited to the promotion of local investment, particularly in the area of promotion of skilled work.

- The consolidation of bargaining power for local materials and products ensuring the development of a genuine local market.

- The immediate and practical realization of architectural structures for housing and other public building operations using these same local materials and building elements.

- The establishment of a genuine focus on real quality, enabling control of materials, products, finished results, based on regulations and recommendations specifically worked out for the particular context.

Mayotte, with its local materials and skills and its building and architectural “intelligence”, is without doubt a model for integrated development which rests fundamentally on the social economy of the building sector and on a real “economic and building ecology”.

Contact US

- Address:Auroville Earth Institute, Auroshilpam, Auroville 605 101 - T.N. India

- Phone:+91 (0) 413 - 262 3330 / 262 3064

- Email:info@earth-auroville.comOpens in your application