Blocks for Roads

September 2010, Auroville – Blocks on the Kindergarten road

CSEB (Compressed Stabilized Earth Blocks) are used to build premises, but can be used also for roads. An experiment was made in Auroville, on the Kindergarten road, on 100 meters length, with around 800 blocks.

The blocks are 24 x 24 x 8 cm. The mix proportion is the same of all the blocks:

– 200 liters of Auroville soil

– 30 liters of sand

– 30 liters of chips gravel

– 1 bag of cement (50 liters) = 13%

– 1/4 bag of lime (10 liters) = 2.61%

Chips gravel was added to increase the load bearing strength but more importantly to increase the resistance to abrasion.

After one month of curing, some blocks have been treated with Zycosoil product, in order to give them a better waterproof resistance. Zycosoil SG nanotechnology has been developed to prepare in-situ waterproofed soil layer, to act like a nano membrane on the compacted soil layer during pavement construction.

The blocks have been differentiated in 3 types:

– Blocks diluted 1/100 of solution Zycosoil – 503 Blocks

– Blocks diluted 1/50 of solution Zycosoil – 196 Blocks

– Blocks without solution – 139 blocks

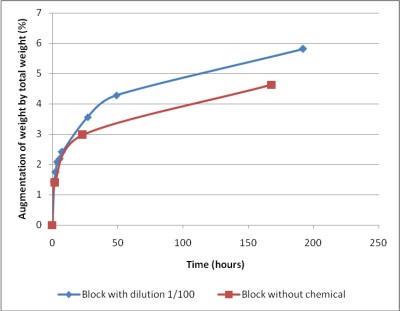

We tested the waterproofing of the Zycosoil product, comparing block with 1/100 solution and block without solution. Below are the results:

The block treated with the Zycosoil product has absorbed more water (5.81% of his weight) than the block that has not been treated (4.63% of his weight). This should have been the opposite and therefore, it seems that the product is not very useful. Nevertheless, the experience has been made only with one block of each type and should have been done at least with 3 blocks. Furthermore, it is possible that a mistake has been done by the workers in the protocol during the immersion of the blocks.

The blocks have been put in place in the road the 6th of October 2010.

July 2011, Auroville – Blocks on the Realization road

Blocks were 24 x 24 x 8 cm. This time, we did not add any chemical, and the mix composition was:

– 130 Liters of Auroville soil

– 40 Liters of sand

– 40 liters of chips gravel

– 1 cement bag = 14% by weight

Contact US

- Address:Auroville Earth Institute, Auroshilpam, Auroville 605 101 - T.N. India

- Phone:+91 (0) 413 - 262 3330 / 262 3064

- Email:info@earth-auroville.comOpens in your application